North Pole - Santa's new Remote Reindeer Workforce (RRW) will be launching this year, providing a huge uplift for the North Pole's distribution operations. In line with what has become the most important theme of 2020, the entire North Pole workforce has transitioned to remote work. The team expects to deliver gifts to children across the globe in record time, without having to leave their home offices.

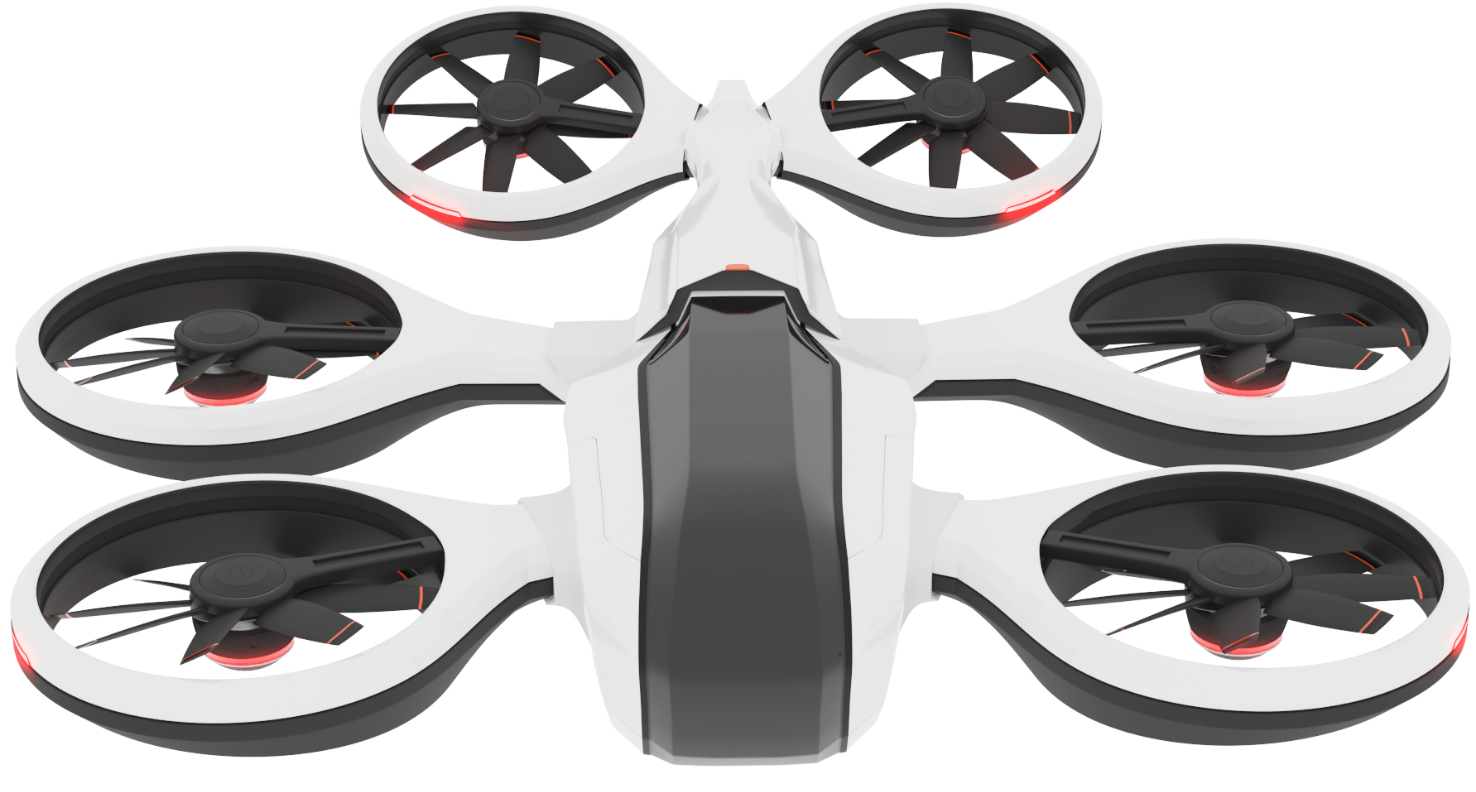

Taking advantage of the latest in drone technology, artificial intelligence, engineering software, and collaboration platforms, Santa's well-loved team of reindeer, under the bright guidance of Rudolph the Red-Nosed Reindeer, coordinated the development and deployment of the new RRW team.

Given Santa’s tight engineering schedule, he decided to leverage Siemens Digital Industries Software and Maya HTT’s simulation, lifecycle management, ECAD/MCAD, manufacturing, and AI-IIoT solutions and services to address the mounting delivery challenges. To be sure the new RRW would be up to the task, the team put their design to the test with virtual multiphysics simulation and validation before building a physical prototype. The results, so far, have been impressive. The RRW team will be fully put to the test, of course, on Christmas Eve.

One of the team's key metrics is wake-up events. "Any time a child wakes up during a gift delivery, it's a sign to us that there's room to improve," said Head Engineer Elf, Merriwinkle. Of the many potential obstacles that could result in a wake-up event, noise is most often the cause.

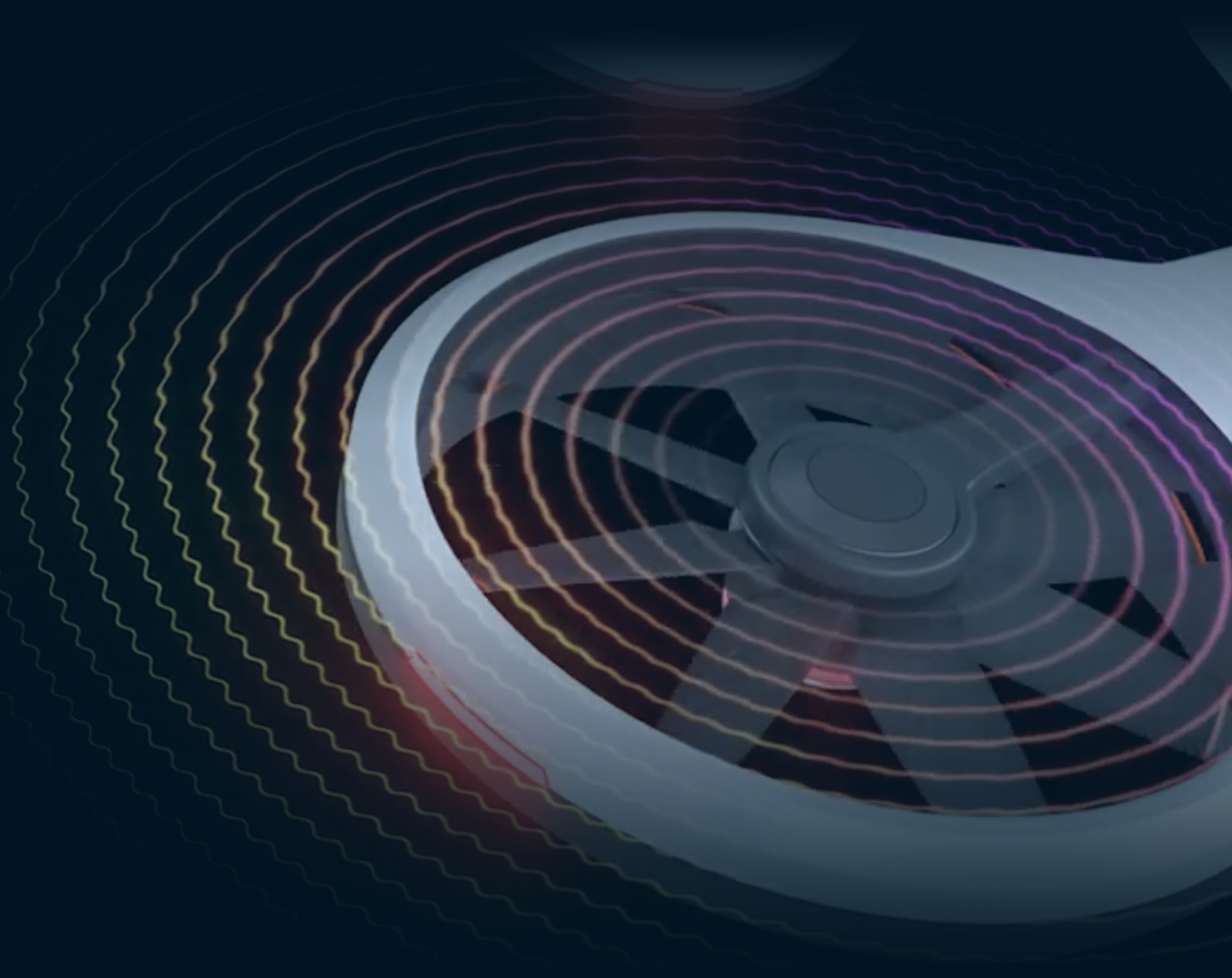

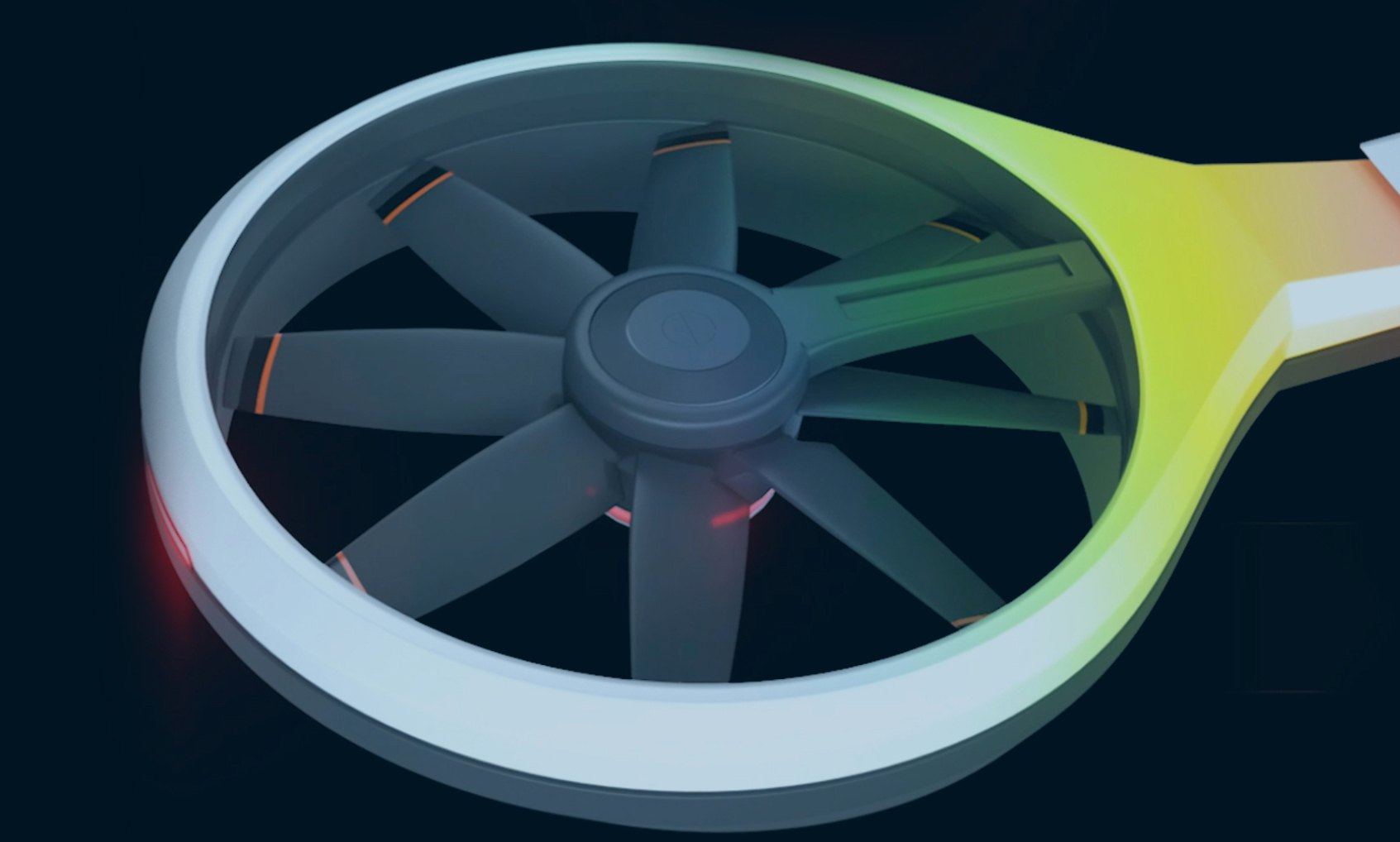

Drones are notoriously noisy. A single drone passing overhead can sound like a swarm of bees, which poses a significant problem for stealth delivery. The RRW was designed with silence in mind, using noise, vibration and harshness (NVH) simulation and analysis. Through acoustic analysis, the Elves were able to design a noise-cancelling device to ensure the rotor noise does not rise above the wake-up decibel threshold and trigger a wake-up event. The RRW is extremely quiet, and the data confirms it.

Taking advantage of new 3D printing capabilities and the advent of additive manufacturing, Santa's Engineering Elves were able to come up with a novel and organic skeleton to ensure structural integrity and provide for optimal aerodynamics, drag, and lift.

Ensuring the delivery at incredible speed requires new structural concepts only possible with topology optimization and additive manufacturing.

Santa and his team of reindeer, meeting by teleconference, confirmed that they're happy to be cozy and warm at home. The Christmas Eve expedition is highly stressful and personally challenging in terms of environmental factors and operational complexity. Each reindeer knows first-hand how extreme the weather can be.

Vortex shedding analysis around the rotors was critical to the project, and helped the Elf Engineers understand the complexity of rotating flows combined with the extreme requirements on the aerodynamics of the drones. The team used best-in-class computational fluid dynamics (CFD) simulation to ensure perfect aerodynamic cruising performance, including subsonic and supersonic flow, low speed and high lift for subsonic configurations, wake dynamics, wake vortex, as well as high speed and high lift for supersonic configurations, and the optimum aerodynamics of the rotors.

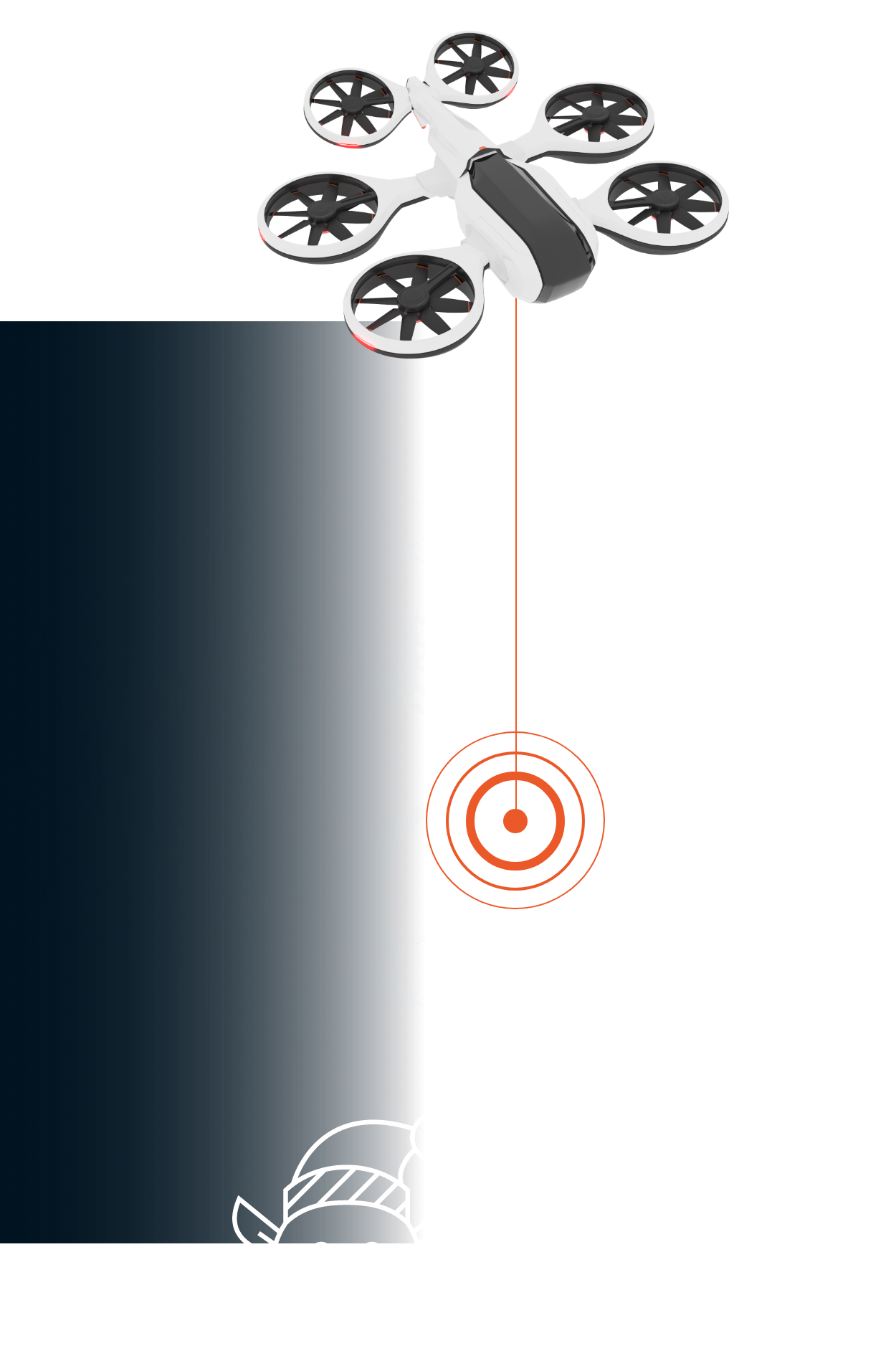

The RRW also features autonomous positioning and sensor-based landing to hover or touch down gently in the best location, allowing for accurate drop-shipping through the chimney or via other access points. Unexpected rooftop obstacles, whether in the form of deep snow accumulation and icy surfaces or satellite dishes and telephone wires, are much less of an issue with this self-guided AI technology. Maya HTT's experience with simulating the extreme conditions of space for space missions was invaluable in helping the elves simulate rooftop landings.

Read about Simulating to the Moon and Mars

As the power density of electronics increases, so too does the amount of heat that must be removed or managed. This is especially problematic for the RRW, as they will have to function well in environments worldwide, and in external conditions ranging from -88 Celsius to +58 Celsius (and climbing). The team used AI-based cold chain packaging simulation and tracking capabilities to validate ahead of time that the payloads would arrive undamaged and in good shape. Leveraging Maya HTT's electronics systems cooling software and expertise, the Engineering Elves created a stellar design for the temperature-sensitive battery components and power system. With input from Maya HTT's experts, the team was able to ensure the battery performance would remain high, guaranteeing maximum flight time with minimal disruptions for battery changes and recharging needs.

This isn't Maya HTT's first time providing guidance on electric engines and battery simulation.

The RRW construction is highly resistant to stresses, from extreme temperatures and precipitation to high winds, icing and debris, as well as bird strikes and lightning strikes. The materials and structural design were optimized to carry as much as possible without sacrificing energy efficiency and speed.

If the load is too heavy or bulky, the drones will be slow and less energy efficient. Too few deliveries per trip will increase the back and forth, with the same effect. In an effort to maximize the gifts one drone could carry, Santa's engineers have been consulting with Maya HTT's team for their expertise with HEEDS. The rotor dynamics and the sizing of the associated structural members have proven to be tricky, given the highly varied gift weight profiles and environmental conditions worldwide to take into account!

The strong collaboration and seamless exchange between the thermal engineering and electrical engineering teams has been greatly facilitated with best-in-class integrated ECAD/MCAD PCB Exchange technology and the Teamcenter lifecycle platform. Although Santa benefits from some international exceptions and regional waivers, the team does have to respect certain air travel regulations. And they can't ignore the safety issues.

Rudolph the red-nosed reindeer denied rumors that he plans to retire down south as early as next year, saying that in fact the new digitalization efforts have brought some exciting new opportunities to his role of Lead Reindeer. He asserted that although the RRW and some parts of the operation have been outsourced to technology, all members of the team are very much involved and needed to run the show from behind the scenes.